What is Tomato Paste aseptic packaging?

Aseptic packaging is a process during which microorganisms are prevented from entering a

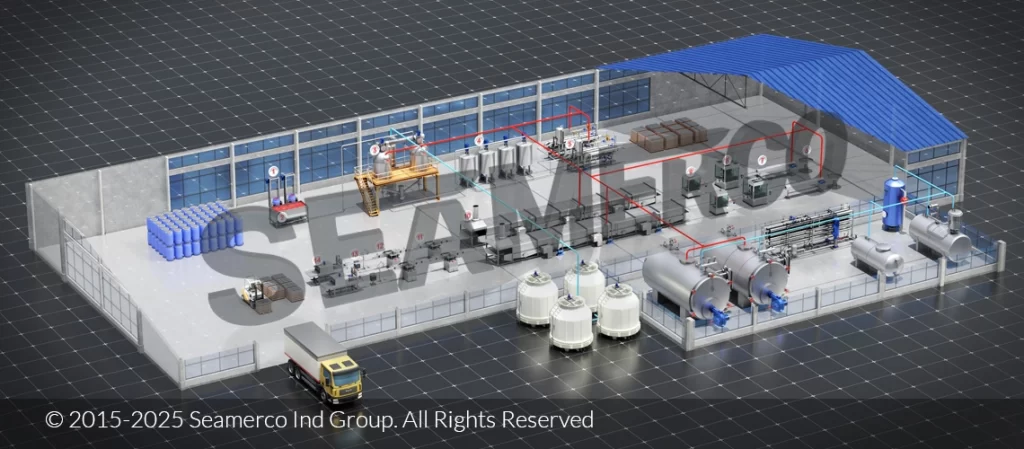

SEAMERCO Industrial Group, a canned tomato paste production and packaging lines manufacturer, offers tomato paste packaging lines in cans & jars. The tomato pastes packaging line made by SEAMERCO Industrial Group and designed with the primary machines, including paste pasteurizer, rotary piston filling, fully automatic four-head capping, three-stage shower Pasteur tunnel, and fully automatic labeling and cartooning section. All SEAMERCO industrial group lines have 18months warranty and 10 years after sales service.

Fresh tomatoes are grinded once they are heated to a temperature of 85 to 100C. The Hot Break product is more viscous, and therefore, denser – its average viscosity ranges from 3.5 to 6 Bostwick centimeters. This type is used for ketchup and other sauces that require 28-30 Brix.

The grinding takes place at lower temperatures: between 65 and 75C. Cold Break processing is used to obtain triple-concentrated tomato paste at 36-38 Brix, Packaged in 500g or 1kg cans for domestic use.

Water adds to the tomato paste so that homogenization occurs with continuous heat. At the end of the dilution, the brix of the tomato paste enters into the Condenser machine and reduces from 36-38 to 25-26 brix.

The diluted tomato paste is transferred to the salt tanks to add 1.5% salt; then transfers to a device called a pasteurizer to raise the temperature and pasteurize it. At the end it goes inside the Pasteur tubes. These tubes perform the pasteurization process surrounds by water vapor at a temperature of 90°.

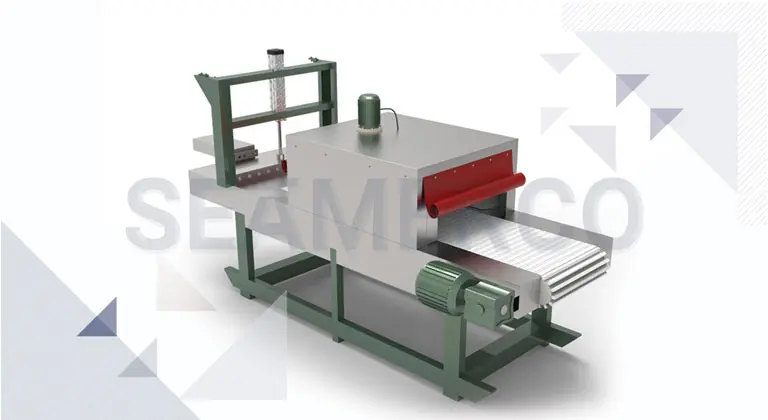

The tomato paste is prepared after the pasteurization stage and ready to be packed in cans & jars at a temperature of 85°c. With each rotation of the filler pistons and the up and down action of the filler packing, the tomato paste is transferred into the pistons. After that, it pours into the can or glass automatically.

Glass cans are filled with tomato paste and transferred into the device using a transfer tape. The can lid’s rail places the glass doors in the path of the glass, so that when the glass passes under the can lid’s rail, the edge of the glass is stuck to the edge of the door. The glass can is moved under the head of the capping machine, and it is fixed to the can by the head of the device.

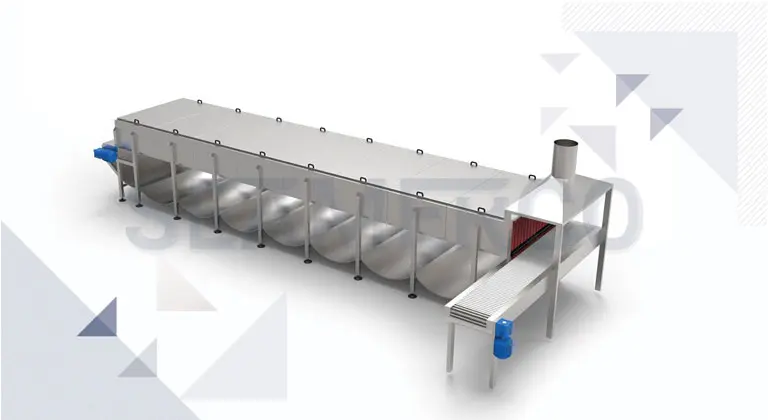

After capping, cans or jars are placed inside the Pasteur tunnel device. After that, the final cooking and pasteurization of the contents inside the can and glass will take place. The Pasteur Tunnel has three stages hot water, lukewarm water, and cold water. In 3 stages cans and jars are showered respectively.

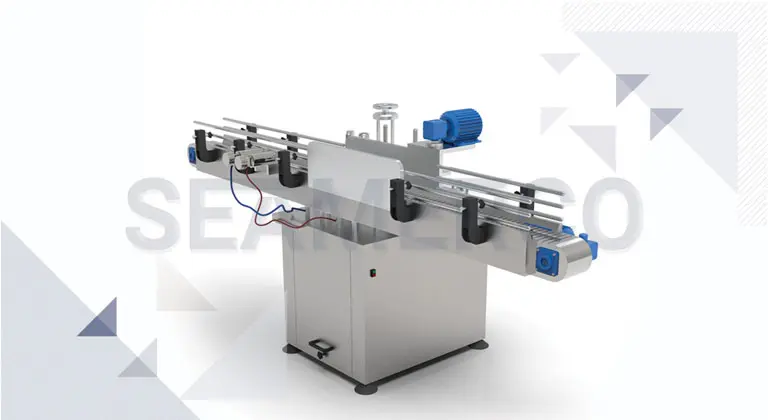

A label is used to display the brand name. At this stage, during contact with jars and label roll, the back of the label is opened and the label sticks to the jars. All of these steps take place automatically without operator intervention.

To diversify the packaging, it is necessary to determine the type of packaging and order a can or glass to produce it. If the fundamental change is in the shape and form of the can or glass, there is a need to place this product in the daily consumption culture of the people, which should be done by planning and advertising.

A capacity that, in addition to justifying fixed and current costs, can introduce your product in the market.

The steps that are usually mentioned in standard phasing are:

Some of the services of Seamerco Industrial Group are as follows.

To answer this question, the advantages and disadvantages of each of them should be considered.

Based on Seamerco’s proposed model for starting a production line, the path of entrepreneurs from the time of the formation of an idea to the production of the final product includes the following.

Knowledge-based performance is one of the most important principles of success. The R&D department of Topmerce is updating and expanding the practical science in the food supply chain every moment, and they do not hesitate to share this knowledge with you.

Aseptic packaging is a process during which microorganisms are prevented from entering a

The increasing expansion of consumer product markets, including food products, has made packaging

Tomato paste is a versatile ingredient used in various cuisines worldwide due to