Automatic Tomato Paste Production line

Tomato paste is one of the most widely used food seasonings worldwide. As

Fresh tomato processing without losing the quality of raw material & least waste. This sentence can cover all the concerns of tomato producers.

The pulping & refining section of this production line with an efficiency of 98% extracts tomato juice to become tomato paste with the best color & texture in the falling-film and forced-circulation evaporators.

Concentration under vacuum & low temperatures completely keeps the properties of raw material and consumption energy get to the lowest possible level.

The crushed tomatoes are get to 85-95°c in pre-heater then in 2 steps the tomato juice is concentrated (double-concentrated) in evaporators. The hot break processing is used for products with higher viscosity and denser, and Brix 28-30 like ketchup

The crushed tomatoes are get to 75°c in pre-heater and in 3 steps tomato juice is concentrated (triple-concentrated) in evaporators. The cold beak processing is used for production packing tomato paste and products with brix 36-38%.

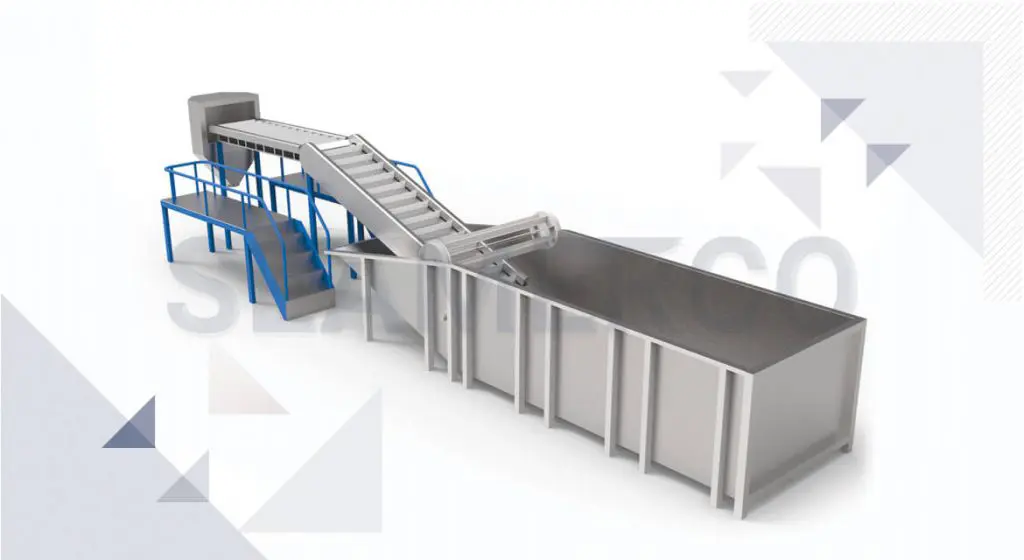

The best & complete way to wash fresh tomatoes is by using a washing bubble system & air blowing. The water circulation pump forces tomatoes to move in the washing laver. The washing progresses is designed in a way that doesn’t damage the raw materials.

The filter separates waste such as leaves & mud from washing tomatoes and returns the clean water to the circulation washing. This process decreases the consuming water of production line in such a way that each dehydrating part can be used for 8 hours.

Tomatoes are rewashed by a high-pressure shower in the elevator and are passed by the conveyor belt in front of the workers so they can remove the tomatoes that are not suitable for processing.

Chopper has 2 mains processes:

One of them is crushing the tomatoes under the pressure of Helis pump and the other one is feeding the production line. In this level the fresh tomatoes are crushed and work being easier to both of machines; preheater and crushing.

Crusher is used for crushing all kind of fruits & vegetables.

In this machine the tomatoes are crushed in to small pieces that is suitable for processing.

This machines is implementer of hot break & cold break. Pre-heater with structure of shell & tube transfers heating crushed tomatoes by steam.

The operation of this machine causes to destruction of enzymes and thus to prevents the hydrolysis of Pectin and loss of the products color.

The heated tomato juice, removed from the preheater machine, is separated from the skin and pulp of the tomatoes by turbo smoothness. This happens when the tomato juice enters the device and passes through the designed meshes. These meshes rotate around a central shaft and create centrifugal force. Then, the skin, tomato seeds, and the hard tissue of the tomatoes are directed to the tomato pomace tank.

An Evaporator turns the purified tomato juice into a tomato paste. The batch evaporator is a device for producing tomato paste in lower capacities. The batch device consists of two jacketed capsules:

A condenser, a water pump, and a system to create a vacuum during cooking. This device converts tomato juice into tomato paste under vacuum at less than 70° c. In this case, the product is made with the best quality.

We introduce the continuous Condenser. This device replaces the batch Condenser for higher capacities. A continuous Condenser uses a plate and pipe system to convert tomato juice into the paste. This device uses vacuum evaporators to concentrate excess water. In this way, the concentration is done in a shorter time and at a lower temperature to increase the color and taste of the tomato paste.

A capacity that, in addition to justifying fixed and current costs, can introduce your product in the market.

The steps that are usually mentioned in standard phasing are:

Yes – with changes in machines and adding machines related to the type of exploitation, it will be possible to produce fruit concentrate.

As these issues have already been mentioned, some things should be considered for this purpose, some of which are:

Some of the services of Seamerco Industrial Group are as follows.

Based on Seamerco’s proposed model for starting a production line, the path of entrepreneurs from the time of the formation of an idea to the production of the final product includes the following.

Knowledge-based performance is one of the most important principles of success. The R&D department of Topmerce is updating and expanding the practical science in the food supply chain every moment, and they do not hesitate to share this knowledge with you.

Tomato paste is one of the most widely used food seasonings worldwide. As

The tomato paste is a paste-shaped material produced if you cook tomatoes for

Tomato paste is one of the most popular food seasonings in the world,